|

Product Name

|

PPGI Color Coated Steel Coil

|

|

|

Brand

|

Gnee

|

|

|

Stantard

|

AISI, ASTM, BS, DIN, GB, JIS

|

|

|

Grade

|

JIS G3312-CGCC, CGC340-570, (G550) ASTM A755M CS-B, SS255-SS550

|

|

|

Width

|

600-1250mm

|

|

|

Thickness

|

0.12-2.5mm

|

|

|

Color

|

according to RAL color or clients' sample

|

|

|

Coil weight

|

3-8 tons

|

|

|

AZ Coating

|

40-275g/㎡

|

|

|

Surface Treatment

|

color coated

|

|

|

Category of painting

|

Polyester

|

PE

|

|

High-durability polyester

|

HDP

|

|

|

Silicon modified polyester

|

SMP

|

|

|

Polyvinylidene fluoride

|

PVDF

|

|

|

Easy-cleaning

|

---

|

|

|

Package

|

standard export packing or as customer's requirements

|

|

|

Application

|

building materials,industrial panels,roofing,etc.

|

|

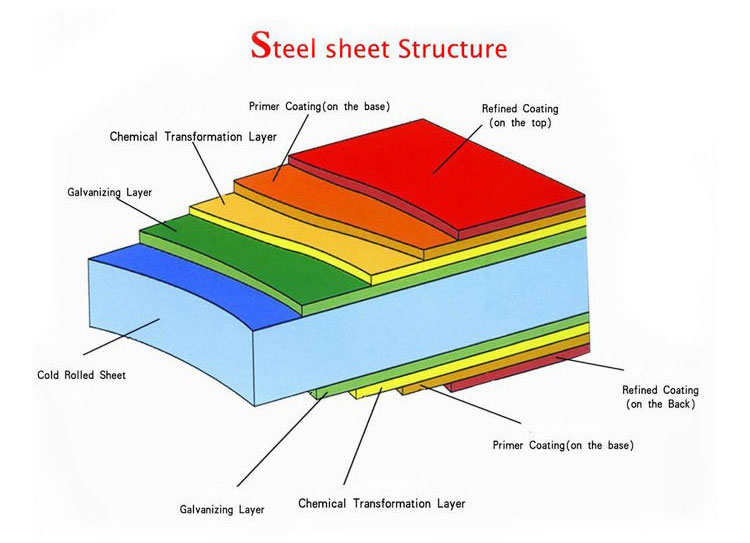

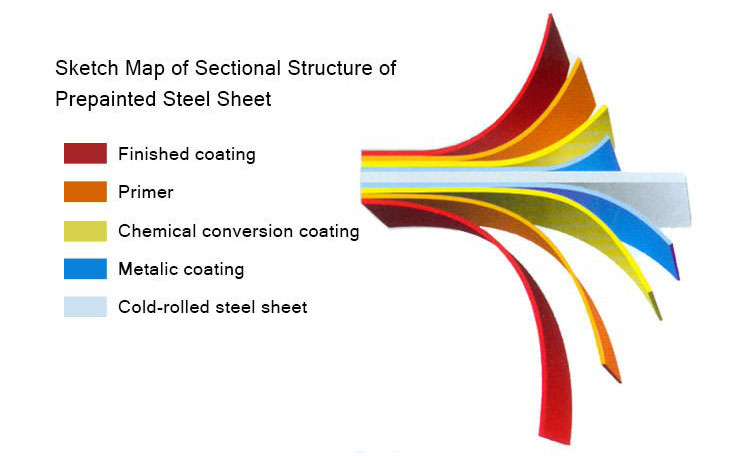

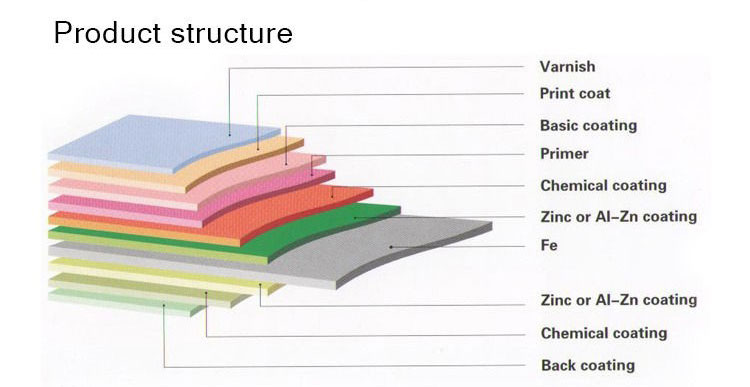

The color coated steel coil is a kind of product made by subjecting the strip steel that continuously degreasing the surface on the production line after chemical treatment such as phosphating, and then baking the strip steel coated with organic paint at high temperature. The surface of this steel sheet has a relatively bright color.

For the use of color-coated steel coils, we have to choose different types of color steel coils to manufacture different products. According to their uses, they are divided into five categories, namely home appliances, decorative materials, building materials, and packaging. Among them, The production process of color coated steel coil for home appliances is very delicate. Of course, the quality requirements of this type of color steel coils are relatively much higher.

1. Polyester color coated sheet

Good adhesion, rich color, wide range of formability and outdoor durability, medium chemical resistance, and low cost.

2. SMP color coated sheet

Silicon modified polyester color coated steel plate, referred to as SMP color steel plate,

3. HDP color coated sheet

High-weather polyester (HDP) uses high-molecular-weight resin, with few polymer branches, stable bond energy, and not easy to be photolyzed, so it is not easy to powder and reduce gloss.

4. PVDF color coated sheet

PVDF fluorocarbon coating is a good material in existing architectural coatings. The coating adopts a patented formula, Kynar500 or kynar5000, inorganic ceramic pigments.

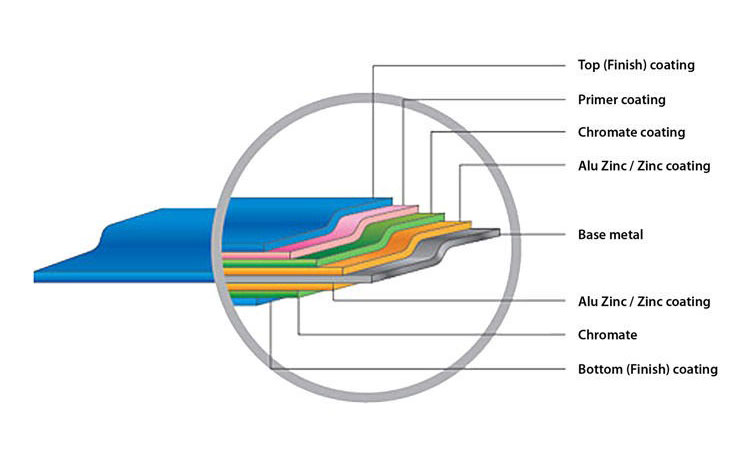

1.Galvanized steel sheet

According to ASTM three-point test, the double-sided coating weight of galvanized steel sheet is 75~700g/㎡. The commonly used galvanized steel sheets in construction applications are Z275 and Z450, and the double-sided galvanizing amount is 275g/㎡ respectively (the thickness of the single-sided coating on the steel plate is 275g/㎡). 19μm) and 450g/㎡.

2. Aluminized steel sheet

There are two common types of aluminized steel sheets for construction:

1)For environments with high heat resistance requirements: the metal coating of this type of aluminized steel plate contains 5-11% silicon, the alloy coating is thin, the weight of the aluminum coating is only 120g/㎡, and the single-sided coating is the smallest The thickness is 20 μm.

2)Used in a highly corrosive environment: almost all of the metal coating is aluminum, the metal coating is thick, the weight of the coating is about 200g/㎡, and the minimum thickness of the single-sided coating is 31μm.

3. Galvalume steel sheet

1) It is a double-sided hot-dip galvalume steel sheet product, the steel sheet base material conforms to ASTM A792 GRADE 80 or AS1397 G550, and its tensile strength is 5600kg/cm. The metallization consists of 55% aluminum, 43.5% (or 43.6%) zinc, and 1.5% (or 1.4%) silicon. It has the long-term corrosion resistance and heat resistance of aluminum; zinc has the protective effect of cutting edge and scratch gap, and a small amount of silicon can effectively prevent the chemical reaction of aluminum-zinc alloy from generating fragments and make the alloy coating more uniform.

2) The three-point test weights of the double-sided coating are 150, 165, and 189 g/cm. The commonly used galvanized steel plate in construction is AZ150, that is, the weight of the coating per square meter is 150 g, and the minimum thickness of the single-sided coating of the steel plate is 20 μm.

4. zinc-aluminium alloy

It is a double-sided hot-dip coated steel plate containing 5% zinc, aluminum, and mixed rare earth alloy.

5 Galvannealed Steel

It is a double-sided galvanized steel sheet product that heat-treats the hot-dip galvanized steel sheet so that the pure zinc coating on the surface is completely converted into a Zn-Fe alloy layer. 180g/㎡.

6 Electro-galvanized steel sheet

It is a pure electro-galvanized plated steel plate product, the maximum weight of double-sided coating is 180g per square meter, and it is generally not used outdoors.

Commonly used in building roofs (and curtain walls) are color galvanized steel sheets and color galvanized steel sheets.

In the future production of color coated steel coils, good substrates will be selected. Of course, this requires that the shape and size of the substrates must be accurate, and then these carefully selected substrates will be used with more complete facilities and improvements. After processing (stronger stability and environmental protection performance), the color steel coil has higher strength and richer colors, which can meet the consumption needs of more consumers.